For decades, recycled raw materials were seen as a secondary or temporary alternative—used only when cost pressures or shortages made virgin materials less accessible. In 2026, that mindset is rapidly changing. Recycled materials are now becoming core production inputs, driven by economic efficiency, supply chain resilience, and evolving regulatory frameworks.

A Structural Shift in Global Manufacturing

Manufacturers across industries are redesigning their sourcing strategies to prioritize recycled inputs from the outset. This shift is no longer driven solely by sustainability goals; it is rooted in cost stability and supply security. Recycled materials often provide more predictable pricing and localized availability, reducing exposure to global commodity volatility.

Cost Efficiency Beyond Procurement

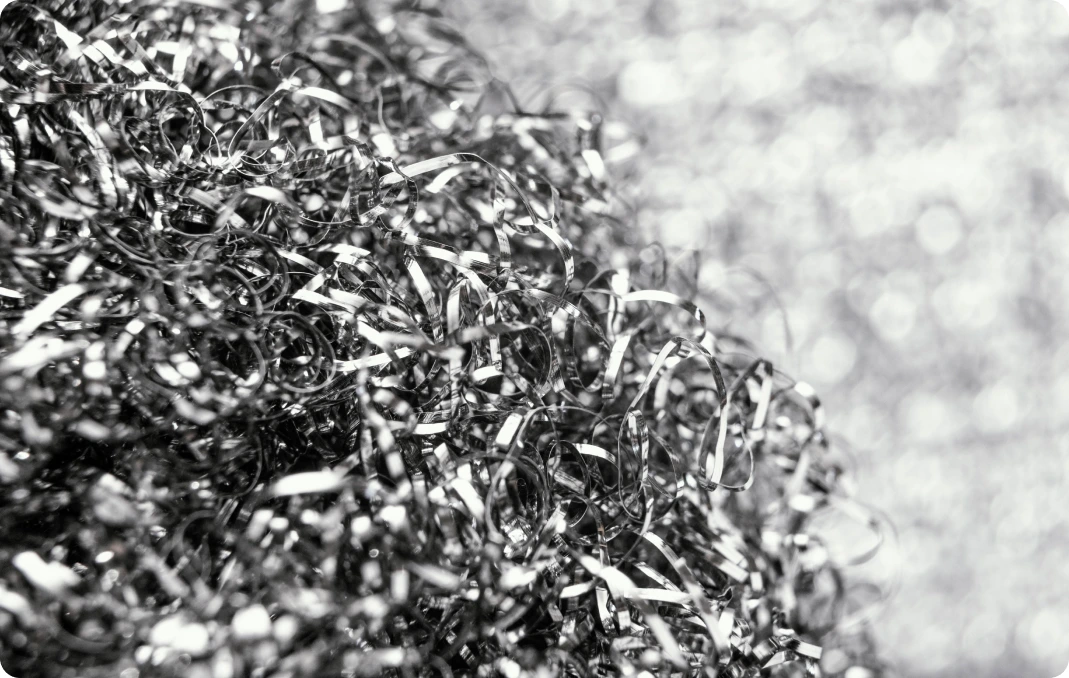

Recycled raw materials frequently require less energy and fewer processing stages than virgin materials. This results in lower operational costs across production cycles. Industries such as construction, packaging, automotive, and consumer goods are increasingly integrating recycled metals, plastics, and fibers to improve margins without sacrificing performance.

Supply Chain Resilience and Localization

By sourcing recycled materials locally or regionally, companies shorten supply chains and reduce dependence on distant suppliers. This localization lowers transportation costs, minimizes delays, and strengthens resilience against geopolitical disruptions and logistical bottlenecks.

Regulatory Alignment and Market Access

Governments and trade blocs are introducing stricter requirements around recycled content, traceability, and environmental impact. Companies that proactively integrate recycled materials position themselves ahead of regulatory changes and gain easier access to international markets where compliance is mandatory.

A Competitive Advantage for the Future

What was once considered a fallback option is now a strategic differentiator. Businesses that treat recycled raw materials as a core input gain cost control, operational flexibility, and stronger positioning in a global market that increasingly rewards circular production models.

At Servicios Integrales de la Costa (SIC), we connect companies with verified suppliers of recycled raw materials, ensuring quality, compliance, and consistent supply to support long-term growth.